株式会社ライジング

作業者が各エリアまで部品や完成品を輸送しておりましたがキャリロがすぐ近くまで取りにきて、

ほしい所に運んでくれるので部品や製品の輸送時間はほぼ0になりました。

ほしい所に運んでくれるので部品や製品の輸送時間はほぼ0になりました。

生産技術次長 四ツ谷様

1.

会社紹介

株式会社ライジングでは、EMS・ODM生産を事業とし電子・機構部品の調達や完成品の実機治具や基板検査治具の製作などハード、ソフト両面でサポート致します。 設計、開発のサポートなど生産以外でもお役に立てるよう、ご提案致しております。 詳しくは、是非弊社ホームページまでお願い致します。

http://www.rising-jpn.co.jp/

2.

CarriRoご導入前のビジネス上の課題

製造物の部品点数が1機種で千数百点、その上増産となり、部品配膳で人手が取られて搬送に人手を回せなくなってきておりました。

この度の新工場は、作業現場を2階にし部品受入と、製品出荷を1階とした為、リフト待ち等で搬送時間が大幅にかかるようになりました。

上記の理由で、3台がフルに部品・製品を完全無人で搬送する事が絶対必要となりました。

この度の新工場は、作業現場を2階にし部品受入と、製品出荷を1階とした為、リフト待ち等で搬送時間が大幅にかかるようになりました。

上記の理由で、3台がフルに部品・製品を完全無人で搬送する事が絶対必要となりました。

3.

CarriRoをご導入された理由

1Fから2Fへの輸送も自動化する計画であったが、走行ルートが非常に長くなる為、磁気テープにて誘導するタイプでは、テープだらけになってしまいルート設定に膨大な時間が掛かってしまう事が予想されました。

また、資材や製造、梱包工程など、輸送先が多いのでルート設定が困難になると予想していました。

キャリロの走行ルート設定はランドマークを用いて最大10m間隔で張り付けるだけ、またルート設定も端末で容易に行える事が導入に至った理由です。

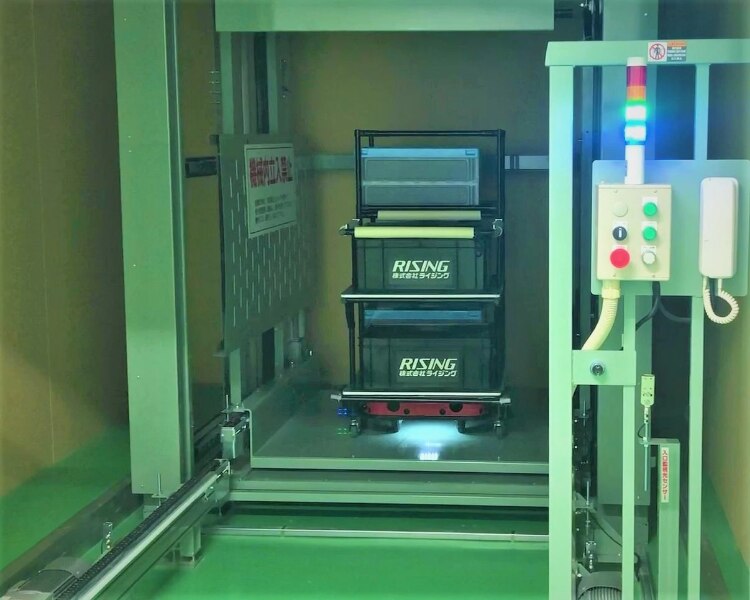

さらにキャリロは外部機器と簡単な設定で連携できる仕様になっていることも導入の決め手となりました。弊社で上位側のシステムを低コストで作り、キャリロから無線で位置情報を送って、リフターや自動ドアなどと連携によって様々な用途に活用が出来ると感じました。

また、資材や製造、梱包工程など、輸送先が多いのでルート設定が困難になると予想していました。

キャリロの走行ルート設定はランドマークを用いて最大10m間隔で張り付けるだけ、またルート設定も端末で容易に行える事が導入に至った理由です。

さらにキャリロは外部機器と簡単な設定で連携できる仕様になっていることも導入の決め手となりました。弊社で上位側のシステムを低コストで作り、キャリロから無線で位置情報を送って、リフターや自動ドアなどと連携によって様々な用途に活用が出来ると感じました。

4.

CarriRoご導入後の効果

これまでは、作業者が各エリアまで部品や完成品を輸送しておりましたがキャリロがすぐ近くまで取りにきて、ほしい所に運んでくれるので

部品や製品の輸送時間はほぼ0になりました。

また、自動ドアやリフターとも連携しているので、部屋にキャリロが入る際や2階層をまたぐ搬送も人手をかけずに自動で行えています。

1周(資材→製造工程→検査工程→出荷工程)150mを3台のキャリロが1日平均30周止まる事無く搬送を行ってます。

1日の移動距離に換算すると150m×3台×30周=13,500m/1日

月に換算すると13,500m×21.5日=290,250m/月

1ヶ月290kmの物の移動を自動化できた事は非常に大きな効果となっております。

省人化の効果としては3名×30万円で90万円/月

年間で1080万円となり1年間で導入費用の回収ができました。

部品や製品の輸送時間はほぼ0になりました。

また、自動ドアやリフターとも連携しているので、部屋にキャリロが入る際や2階層をまたぐ搬送も人手をかけずに自動で行えています。

1周(資材→製造工程→検査工程→出荷工程)150mを3台のキャリロが1日平均30周止まる事無く搬送を行ってます。

1日の移動距離に換算すると150m×3台×30周=13,500m/1日

月に換算すると13,500m×21.5日=290,250m/月

1ヶ月290kmの物の移動を自動化できた事は非常に大きな効果となっております。

省人化の効果としては3名×30万円で90万円/月

年間で1080万円となり1年間で導入費用の回収ができました。

5.

今後の展開

・他工場での展開及び、生産管理・物流システムとの連携を自社開発で実現

・CarriRoの使用範囲を広げ省力化実施

・CarriRoの使用範囲を広げ省力化実施

6.

構内レイアウト概観図

お電話でお問い合わせ

tel 03-5802-6901 fax 03-5802-6908

メールでお問い合わせ

© ZMP INC. All Rights Reserved.