物流支援ロボット CarriRo® AD外部機器連携モデル、 電子機器製造工場にて導入

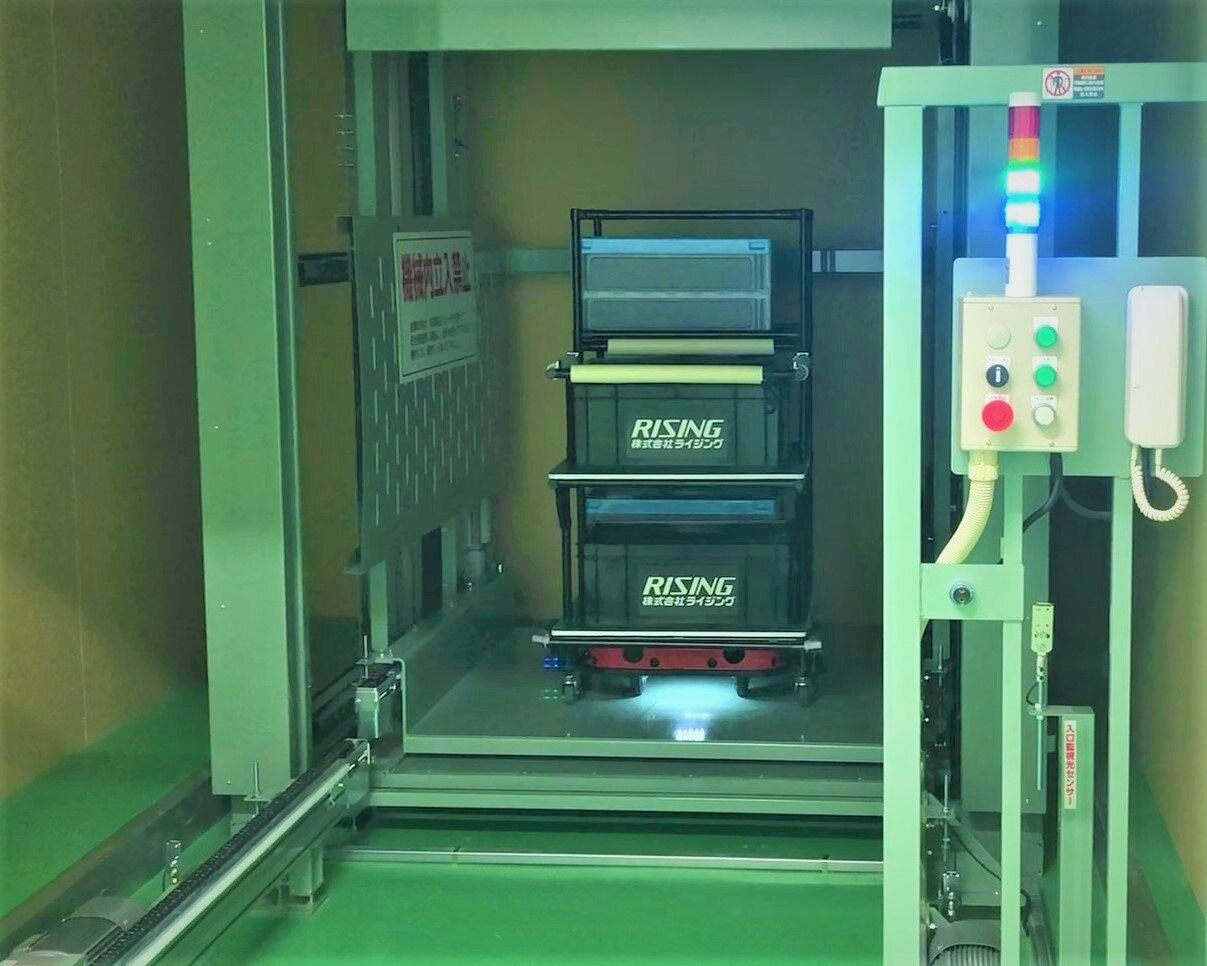

-自動ドア・リフターなどと連携し、階層間の搬送の工数ゼロを実現-

【CarriRoⓇ 導入事例紹介】株式会社ライジング

事例URL:https://www.zmp.co.jp/carriro/detail_rising.html

株式会社 ZMP(東京都文京区、代表取締役社長:谷口 恒、以下 ZMP)が2019年3月から販売している物流支援ロボット CarriRo®(キャリロ)AD外部機器連携モデルは、株式会社ライジング(本社:大阪府大阪市、代表取締役:西田洋一)の電子機器製造を行う工場において、搬送作業の自動化及び省人化のために導入されました。

株式会社ライジング(http://www.rising-jpn.co.jp/)は、EMS・ODM生産を事業とし、電子・機構部品の調達や完成品の実機治具や基板検査治具の製作などハード、ソフト両面でサービス展開されております。

同社生産技術課長の四ツ谷様は導入前の事業上の課題として、製造物の部品点数が多く増産も重なったため、搬送に人手を回せない状況となってしまった。そのため部品及び製品を完全無人で搬送することが絶対的に必要となった、とコメントされております。

またCarriRo® AD外部機器連携モデルを導入された背景として、自動搬送が階層をまたぐこともあり、走行ルートが非常に長くなる為、磁気テープにて誘導するAGVでは、テープだらけになってしまいルート設定に膨大な時間が掛かってしまう事が予想された。また、資材や製造、梱包工程など、輸送先が多いのでルート設定が困難になることも懸念でした。一方、CarriRo® ADの走行ルート設定は簡単、またフレキシブルなルート設定も端末で容易に行える事が導入に至った理由です。

さらにCarriRo® ADは外部機器と簡単な設定で連携できる仕様になっていることも導入の決め手となりました。ユーザー側で上位のアプリケーションを作り、キャリロから無線で位置情報を送って、リフターや自動ドアなどと連携によって様々な用途に活用が出来ると感じた、コメントされております。

ご導入後の効果としては、これまでは、作業者が各エリアまで部品や完成品を輸送しておりましたが、CarriRo® ADがすぐ近くまで取りにきて、ほしい所に運んでくれるので部品や製品の輸送時間はほぼゼロになった。また、自動ドアやリフターとも連携しているので、部屋にキャリロが入る際や階層をまたぐ搬送も人手をかけずに自動で行えている、とのことです。

今後の展開として、現在松阪工場で3台稼働しておりますが、他工場への展開を検討されております。

CarriRo® AD外部機器連携モデルは、可変ランドマークを検知したタイミングで、予め設定された信号をCarriRo® ADから外部機器に出力し、その出力信号に基づきPLC(Programmable Logic Controller)※などの外部機器の制御を行うことができます。一方、外部機器側からはCarriRo® ADに対して発進や停止などの走行指示を入力してCarriRo® ADを制御することもできます。

この機能を活用することによって、例えば以下のような運用が可能になります。

・ 自動牽引離脱装置と連携させ、特定の位置で牽引している台車を自動で切り離す

・ PLCと連携させ、シャッターの開閉や、エレベーター・リフターへの乗り降りを自動で行う

・ PLCと連携させ、複数台のCarriRo® ADの走行状態(走行中、停止中)などを管理する

・ コンベアーと連携させ、CarriRo® ADから荷物を自動で積み下ろしする

※PLC(Programmable Logic Controller)とは、別名シーケンサともよばれ、予め組んだプログラムにもとづき、自動で外部の機器を制御(コントロール)できる電子機器です。工場などでは普及が進んでおりますが、PLCにより汎用的にエレベーター、自動ドア、リフターなどの制御に使用されています。

【製品Web URL】https://www.zmp.co.jp/carriro/

【動画】https://youtu.be/aczJ_RfQ9lY

【製品価格】

CarriRo® FD(2019年モデル):5年リース 月額34,000円(税別)/1台

CarriRo® AD:5年リース 月額52,000円(税別) / 1台

CarriRo® AD(外部機器連携モデル):5年リース 月額58,000円(税別) / 1台

【主な仕様】

本体重量 | 55kg |

大きさ | 幅61cm×奥行91cm×高さ24cm ※ハンドル部96cm |

最大積載荷重 | 150kg |

最大速度 | 時速6km(ドライブ、追従モード) 時速3km(自律移動モード) |

牽引力 | 250N (300kg相当) ※路面状況や台車の状況によります。 |

充電時間 | 2時間半 |

稼働時間 | 8時間 ※稼働状況によって異なる可能性があります |

【製品紹介HP】

https://www.zmp.co.jp/carriro/

※こちら導入事例等もございますのでご覧ください。

【関連情報】

外部入出力機能搭載モデル

https://www.zmp.co.jp/products/carriro/carriro-plc

【プレスリリース記事】

プレスリリースPDFはこちらからご確認いただけます。