物流支援ロボットを活用した物流業界向けソリューションの 実証実験の開始について

-自動運転向けクラウドサービスROBO-HI®、物流支援ロボットCarriRo®を活用し、

IoTサービス連携によるネットワーク環境の提供-

株式会社ZMP(東京都文京区、代表取締役社長:谷口 恒、以下ZMP)と東日本電信電話株式会社(東京都新宿区、代表取締役社長:井上 福造、以下NTT東日本)は、株式会社NTTロジスコ(東京都大田区、代表取締役社長:東明彦、以下NTTロジスコ)の物流現場における実証実験を2019年7月24日より開始しました。

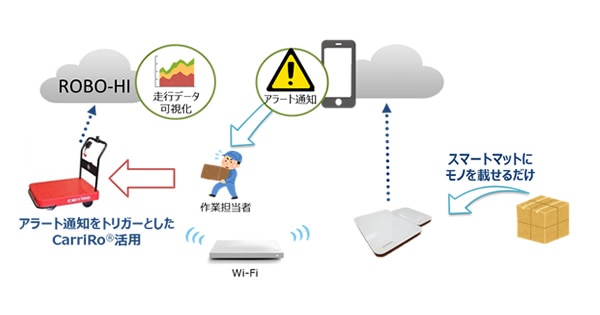

本実証実験では、自動運転向けクラウドサービスであるROBO-HI®を物流支援ロボットCarriRo®(キャリロ)と連携させ、Wi-Fi経由でCarriRo®の運用状況の可視化を行うとともに、荷重計測のできるIoT重量計スマートマット※を活用した物流倉庫内ネットワーク環境の提供、ソリューションの高機能化を図ります。これらの物流現場におけるソリューションの実用性および導入効果に関する検証を実施します。

※株式会社スマートショッピングが2018年10月から提供している重量センサの搭載された重量計です。Web管理画面で在庫の残量・残数チェックや在庫重量が一定の閾値を上回る、または下回ると、その情報がWi-Fi経由で指定の連絡先へ通知されます。スマートマットは、在庫の見える化や補充効率化、在庫推移のデータ化、発注自動化等を目的に多様な業種で利用されています。

■本実証実験に至った背景

ZMPでは、CarriRo®のWi-Fi対応にあたり、導入いただくお客様のネットワーク環境の整備や構築、運用後のサポート体制が必要となりました。一方、NTT東日本では、様々なお客様がIoT機器やAI技術を手軽に導入できるパッケージサービスの提供をめざしております。NTTロジスコも今後予想される人手不足などに対応していくために、効率化・省人化に向けたソリューションの導入が課題となっております。こうした各社の背景を踏まえ、物流現場への新たなソリューションの提供に向けて、CarriRo®やIoT機器を活用した業務効率化の実証実験を行います。

■本実証実験の概要

NTTロジスコの物流センター内にてWi-Fi対応したCarriRo®とスマートマットを使用し、廃ダンボールや空きかごの回収等の業務に活用します。ROBO-HI®にてCarriRo®の運用状況を確認し、効果の検証を行うと共に、IoTサービスを含むネットワーク環境や運用面での課題や必要となるサポートの検討を行います。

■本実証実験における各社の役割および目的

<ZMP>

ZMPは、本実証実験において、CarriRo®のWi-Fi対応を実現するとともに、ROBO-HI®との連携を実現し、CarriRo®のルート管理や稼動状況等のステータス管理ができる機能を提供いたします。CarriRo®の情報をWi-Fi経由でROBO-HI®に集約し一元的に管理することで、物流センター内におけるCarriRo®活用の利便性向上につなげます。

<NTT東日本>

NTT東日本は、本実証実験において、スマートマットを活用したIoTサービスの検証を実施いたします。

スマートマットを物流センター内の任意のエリアに敷設し、スマートマット上に集積された対象物の重量が一定の閾値を上回る、または下回ると、その情報がWi-Fi経由で指定の連絡先へ通知されます。その通知をトリガーに、CarriRo®を発進させると自律走行により指定の場所へ対象物を搬送いたします。本ソリューションの提供に必要となるネットワーク環境やサポートを今回の実証実験を通じて確認することで、ネットワーク環境の構築から運用まで含めたサポートの検討を行います。

<NTTロジスコ>

NTTロジスコは、本実証実験において、自社の業務効率化に向けて物流センター等の実証実験フィールド環境を提供いたします。

CarriRo®とスマートマットを組み合わせたソリューションに適合する自社センター内の業務選定、走行環境やネットワーク環境の構築、運用設計を実施し、実証実験で得られた結果について省人化効果とフィージビリティを検証します。また、物流センターオペレーションを担う視点での効果的な活用方法と適合する利用シーンを提案します。

■今後の展望

<ZMP>

ZMPは、ROBO-HI®によるCarriRo®の運用状況の可視化に加え、ROBO-HI®によるCarriRo®の複数台同時制御を実現します。

<NTT東日本>

NTT東日本は、「ROBO-HI®によるCarriRo®の複数台同時制御」の実現に合わせて、ZMPと連携しスマートマットからROBO-HI®を経由したCarriRo®への人手を介さない走行指示(「スマートマット~ROBO-HI®~CarriRo®」間の完全自動連携)の実現により業務効率の向上を目指すとともに、CarriRo®ユーザーへWi-Fi等の物流倉庫内ネットワーク環境の構築から運用まで含めたトータルでのサポートを実現していきます。

<NTTロジスコ>

NTTロジスコは、CarriRo®やスマートマットといった技術の適用範囲を広げ、お客様の物流業務効率化・人手不足・品質担保等の課題解決をご提案していきます。

本実証実験での成果を基に、3社は物流業界の課題解決手法として、物流支援ロボットやIoT機器の導入による業務自動化、それらに必要なネットワーク環境の構築支援等により、物流業界の効率化・省人化を実現するトータルソリューションの提供に向けた検討を進めてまいります。

将来的には、様々な自動搬送ロボットやIoT機器がROBO-HI®を介して相互に接続し、IoT機器の発信する信号により自動搬送ロボットが自動走行を開始する業務の完全自動化等、物流業界の業務効率化・人手不足等の課題解決に貢献していきます。

《参考》

【実証実験イメージ】

【参考:「CarriRo®」について】

物流支援ロボットCarriRo®は、ZMPが開発に取り組む自動タクシー®のサービス実証に代表されるZMPの自動運転技術を応用して開発された製品です。少子高齢化の流れにより急速な人手不足となっている物流業界において搬送作業の負荷を軽減し、省人化・効率化を目的として販売を実施しております。現在販売開始から累計100 ユーザー以上の導入実績があり、自律移動による新たな付加価値により物流拠点や工場を始め、ホテル等のサービス業界と様々な分野に導入が広がっております。

【製品Web URL】https://www.zmp.co.jp/carriro/

【動画】https://youtu.be/dkfvVXNdaCU

【製品価格】

CarriRo® FD (2019年モデル):5年リース 月額34,000円(税別)/1台

CarriRo® AD:5年リース 月額52,000円(税別) / 1台

CarriRo® AD(外部入出力機能搭載モデル):5年リース 月額58,000円(税別) / 1台

【主な仕様】

本体重量 | 55kg |

大きさ | 幅61cm×奥行91cm×高さ24cm ※ハンドル部96cm |

最大積載荷重 | 150kg |

最大速度 | 時速6km(ドライブ、追従モード) 時速3km(自律移動モード) |

牽引力 | 250N (300kg相当) ※路面状況や台車の状況によります。 |

充電時間 | 2時間半 |

稼働時間 | 8時間 ※稼働状況によって異なる可能性があります |

【製品紹介HP】

https://www.zmp.co.jp/carriro/

※こちら導入事例等もございますのでご覧ください。

【東日本電信電話株式会社】

https://www.ntt-east.co.jp/

本社:東京都新宿区 代表取締役社長:井上 福造

東日本地域(※)において、最先端のICT技術を活かしたサービスの開発・販売、通信回線や基幹ネットワークの構築・運用等を行い、ビジネス・ライフスタイルの革新、安心・安全な社会を支える地域通信会社です。

(※)新潟、長野、神奈川以東の17都道県

【株式会社NTTロジスコ】

https://www.nttlogisco.com/

本社:東京都大田区 代表取締役社長:東 明彦

NTTグループにおける唯一の総合ロジスティクス企業として誕生し、荷主企業に対し物流改革を提案し、包括して物流業務を受託する3PL企業として、全国16の物流センターで事業を展開しています。NTTグループの物流のコスト削減及び品質向上に加え、NTTグループ以外の物流業務において、ルーター等の検査や設定も行うIT機器物流、人工関節やカテーテルを取り扱う医療機器物流、化粧品や健康食品の通信販売物流、通信機器や医療機器の24時間緊急配送業務等、特色のあるサービスを提供しています。

【第1回 CarriRo® EXPO特設ページ】https://www.zmp.co.jp/event/carriro-expo2019

【お申し込み方法】

以下の予約申し込みページよりお申込みをお願いします。

参加お申し込みページ:https://www.zmp.co.jp/products/zmpworld2019/yoyaku

※競合製品をお取り扱いされている場合など、お断りさせて頂く場合があります。

予めご了承ください。

【ZMP World 2019開催概要】

テーマ:『R&Dから量産化へ -ZMPが起こすロボリューション-』

開催日時:2019年7月23日(火)~26日(金)10:00~18:00

会場:ベルサール飯田橋ファースト (東京都文京区後楽2-6-1 住友不動産飯田橋ファーストタワー)

参加費:無料(懇親会は有料となります)

特設ページ:https://www.zmp.co.jp/products/zmpworld2019

【プレスリリース記事】

プレスリリースPDFはこちらからご確認いただけます。