物流支援ロボット CarriRo® 全国導入説明会開催

-日本全国主要4都市にて開催、最新モデルの追従機能を体験可能-

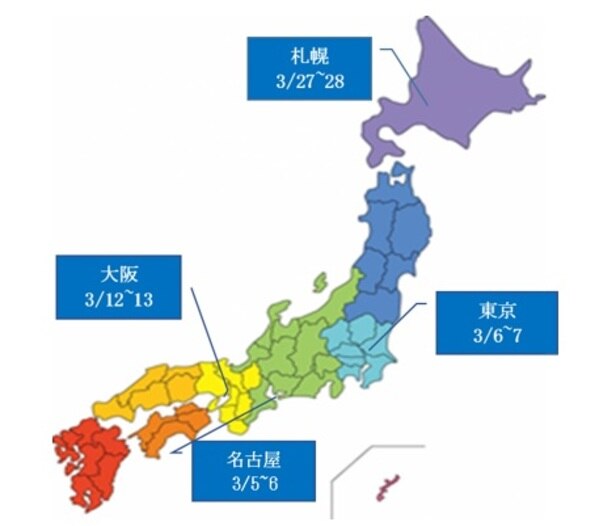

開催会場と日程

CarriRo®最新モデル

株式会社ZMP(東京都文京区、代表取締役社長:谷口 恒、以下ZMP)は、CarriRo®(キャリロ)FD(追従モデル)の2019年モデルを2019年3月より出荷開始いたします。そのリリースにあたり導入をご検討いただく機会として、CarriRo®販売代理店および提携先のご協力により、日本全国の主要都市にて事前登録制で「全国導入説明会」を開催いたします。

物流支援ロボットCarriRo®は、ZMPが開発に取り組む自動タクシー®のサービス実証に代表されるZMPの自動運転技術を応用して開発された製品です。少子高齢化の流れにより急速な人手不足となっている物流業界において搬送作業の負荷を軽減し、省人化・効率化を目的として販売を実施しております。現在販売開始から累計100ユーザー以上の導入実績があり、自律移動による新たな付加価値により物流拠点や工場を始め、ホテルなどのサービス業界と様々な分野に導入が広がっております。

追従性能の向上、障害物センサの改良、また、接触センサや英語・中国語の海外言語対応を標準搭載した2019年モデルは、より高い安全性で直感的に使用できるため、従来モデルよりも活用いただける現場が広がります。

この機会に実機をご覧頂き、導入をご検討下さい。

【全国導入説明会 開催概要】

各回開催時間:①9:30~ ②11:30~ ③14:00~ ④16:00~

中部方面・愛知 |

関東方面・東京 |

3月5日(火) ~ 6日(水) |

3月6日(水) ~ 7日(木) |

愛知県名古屋市中区錦1丁目11番20号 大永ビル5F 凸版印刷株式会社 中部事業部 DX-GATE |

東京都品川区西五反田1丁目31番1号 日本生命五反田ビル ロジスティックスオペレーションサービス株式会社 |

関西方面・大阪 |

北海道 |

3月12日(火) ~ 13日(水) |

3月27日(水) ~ 28日(木) |

大阪府大阪市中央区南船場1-16-4 株式会社三洋 |

北海道江別市東野幌町44-1D棟 北海道ロジサービス株式会社 |

※日程ほか詳細は随時【参加お申込みページ】にて更新されますのでご注意ください。

【参加お申し込みページ】

※QRコードは株式会社デンソーウェーブの登録商標です。

以下リンクよりご登録の上、是非ご参加ください。

登録フォーム: https://bit.ly/2TYhmy8

【製品Web URL】https://www.zmp.co.jp/carriro/

【動画】https://youtu.be/dkfvVXNdaCU

【製品価格】

CarriRo® FD (2019年モデル (追従機能)):5年リース 月額34,000円 (税別) /1台

CarriRo® AD (自律移動モデル):5年リース 月額52,000円 (税別) / 1台

【主な仕様】

本体重量 |

55kg |

大きさ |

幅61cm×奥行91cm×高さ24cm ※ハンドル部96cm |

最大積載荷重 |

150kg |

最大速度 |

時速6km(ドライブ、追従モード) 時速3km(自律移動モード) |

牽引力 |

250N (300kg相当) ※路面状況や台車の状況によります。 |

充電時間 |

2時間半 |

稼働時間 |

8時間 ※稼働状況によって異なる可能性があります |

※「自律移動モデル」の上記仕様は基本的に2019年モデル(追従機能)と同一と想定していますが、今後変更の可能性がございます。

【プレスリリース記事】

プレスリリースPDFはこちらからご確認いただけます。