パレット搬送のカギとなるフォークリフトが遂に自動化!

用途に合わせて『ウォーキー』と『リーチ』の

2つのタイプを販売しております。

無人フォークリフトCarriRoⓇ Fork

概要・特徴

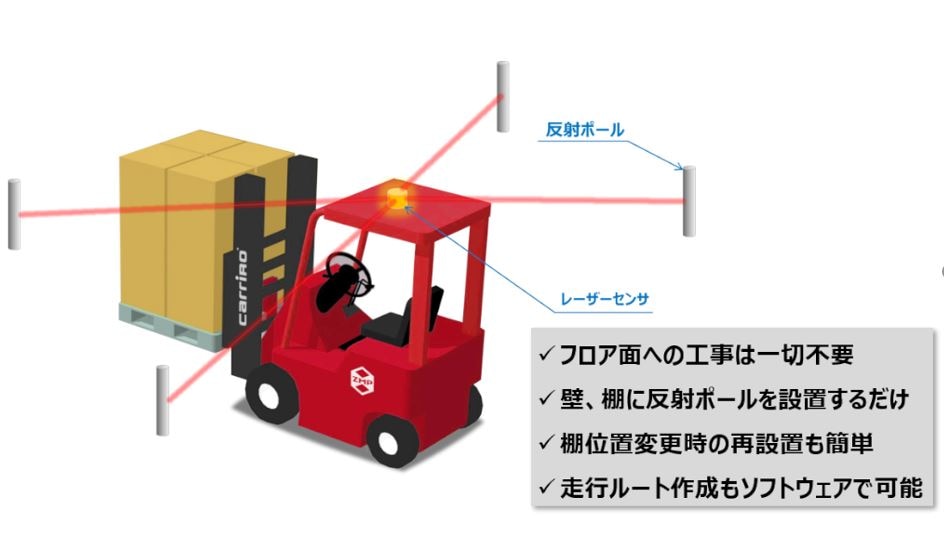

CarriRo Forkは、独リンデ・マテリアル・ハンドリング社(以下、リンデ社)フォークリフトに、ZMP独自開発の自動運転OS「IZAC®(アイザック)」を搭載した無人フォークリフトです。自動走行のための自己位置認識手法として床面工事が不要なレーザー誘導方式を採用、従来の磁気テープ敷設方式に比べルート変更時にかかるコストを大幅に削減しています。

本最新モデルでは従来機より約20%の高速化を実現。また、ZMP独自開発のクラウド型マルチロボOS 「ROBO-HI®(ロボハイ)」と連携することで、遠隔からの稼働状況の監視に加え、複数のCarriRo Fork利用時の優先走行制御や自動倉庫・垂直搬送機等の設備とのシステム連携も可能です(オプション)。 可搬重量最大1.4t・揚高最大約6mの「リーチタイプ」と、可搬重量最大650kg・揚高最大約3mの「ウォーキータイプ」の2機種をラインナップしています。

本最新モデルでは従来機より約20%の高速化を実現。また、ZMP独自開発のクラウド型マルチロボOS 「ROBO-HI®(ロボハイ)」と連携することで、遠隔からの稼働状況の監視に加え、複数のCarriRo Fork利用時の優先走行制御や自動倉庫・垂直搬送機等の設備とのシステム連携も可能です(オプション)。 可搬重量最大1.4t・揚高最大約6mの「リーチタイプ」と、可搬重量最大650kg・揚高最大約3mの「ウォーキータイプ」の2機種をラインナップしています。

無人フォークリフト CarriRo Forkのラインナップ

無人フォークリフトを実現する原理・技術

フォークリフトを自動運転するために、2D-LiDARを活用した自動運転技術を採用しています。この方式を「レーザー誘導型」方式と呼んでいます。

本方式により、床面などに加工が必要がないことや、反射板が見えていればルートの設定が柔軟に行えるというメリットがございます。

また、無人フォークリフトを活用した安全装備や連携技術についても詳細にて確認いただけます。

本方式により、床面などに加工が必要がないことや、反射板が見えていればルートの設定が柔軟に行えるというメリットがございます。

また、無人フォークリフトを活用した安全装備や連携技術についても詳細にて確認いただけます。

レーザ誘導型の無人制御イメージ

フォークの幅広いオペレーションに対応する製品オプション

無人フォークリフトの仕様

| ウォーキー | リーチ | |

| 外寸(約) | 全長2,510mm×全幅1,402×全高2150mm | 全長2,307mm×全幅1,380×全高2850mm |

| 可搬重量 | ~650kg | ~1,400kg |

| 最大揚げ高 | 2,924mm | 5,920mm |

| 最大速度 | 3.6km/h~ | |

| 車両重量 | 1,815kg | 2,975kg |

| 移動精度/停止精度 | 約±100mm/±20mm~ | |

| 安全機能 | 障害物センサー、緊急停止ボタン、バンパーセンサー | |

本製品仕様は、弊社評価基準に基づくものとなっております。また性能改善のため予告なく変更の場合がございます。

© ZMP INC. All Rights Reserved.