物流支援ロボットCarriRo®、食品業界向けソリューション資料公開

-夏の繁忙期に向け、食品業界向け導入サポートキャンペーン開始-

株式会社ZMP(東京都文京区、代表取締役社長:谷口 恒、以下ZMP)が販売している物流支援ロボットCarriRo®(キャリロ)はこれまで、250社を超える企業に導入、活用されております。その中でも、コロナ禍のなか、巣ごもり消費を背景に食品・飲料系倉庫における物量が急増、また、これからの季節(繁忙期)に向け作業者の人手不足や作業負荷が大きな課題となっております。従来の手作業による搬送だと、人やモノとの接触が多くなり感染症発生のリスクも高まります。そのための対策として搬送の省人化並びに非接触化が可能な自動搬送ロボットやAGVの導入検討をされる企業が多くなっております。

このような食品・飲料系倉庫における課題を解決するために、CarriRo®による自動搬送ソリューションを資料として公開するとともに、導入後すぐに運用を開始いただけるサポートプランをご提供いたします。

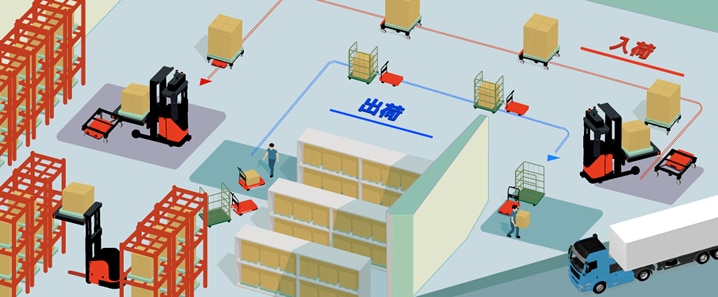

CarriRo導入後の入出荷作業での運用イメージ

CarriRo導入後の入出荷作業での運用イメージ

〇一般的な食品・飲料系倉庫での搬送業務

入荷:パレットで入荷し、フォークリフトで搬送、保管エリアの棚に格納する。

出荷:スリムカート又はカゴ台車でピッキング。その後バースまで作業者が人手で搬送、所定の位置に置き、トラックに積み込む。

〇一般的な運用上の課題

・フォークリフトの稼働台数が多い、人件費負担及び安全上の課題がある。

・ピッキングに多くの人手が必要となる。また飲料の場合には重量が重く、搬送頻度も高いため、作業員への負荷が大きい。

〇キャリロを活用した運用

入荷:無人フォークリフトCarriRoFork又はCarriRo®AD+(パレット積載タイプ)を用いて自動搬送

出荷:スリムカート又はカゴ台車を使用する場合には、AD+(台車タイプ)を用いて牽引

ピッキング時は柔軟な動きが求められるため追従機能を活用

バース迄の搬送時は、自律移動機能に切り替え、自動搬送を行う

ここで自動離脱アタッチメントを用いればさらに省人化効果が上がる

【食品業界向けソリューション資料】

ダウンロードリンク:https://www.zmp.co.jp/products/catalog/carriro-solution

〇参考運用事例

ヤマエ久野様:https://www.zmp.co.jp/carriro/casestudy/detail_yamaehisano

北海道ロジサービス様:https://www.zmp.co.jp/carriro/casestudy/detail_hokkaido-logi

物産ロジスティクスソリューションズ様:https://www.zmp.co.jp/carriro/casestudy/detail_bls.html

※ヤマエ久野様は7月13日-15日に開催されるZMPworld2021内でユーザー様としての講演も予定しております。

【自律移動導入サポートの無償提供について】

想定運用をもとにルート設置や設定作業を弊社専門スタッフにより実施させていただきます。自律移動導入サポートをご活用いただくことで、現場のリソースを使うことなく、納品後半日程度で本格運用を開始できます。なお、本サービスの無償提供については、2021年9月末までに自律移動モデル(CarriRoAD又はAD+)をご導入いただいた場合となります。

【物流支援ロボットCarriRo】

物流支援ロボットCarriRo®は、ZMPが開発に取り組む自動タクシー®のサービス実証に代表されるZMPの自動運転技術を応用して開発された製品です。少子高齢化の流れにより急速な人手不足となっている物流業界において搬送作業の負荷を軽減し、省人化・効率化を目的として販売を実施しております。現在販売開始から累計250ユーザー以上の導入実績があり、自律移動による新たな付加価値により物流拠点や工場を始め、ホテルなどのサービス業界と様々な分野に導入が広がっております。

【製品Web URL】https://www.zmp.co.jp/carriro/

【動画】https://youtu.be/dkfvVXNdaCU

【製品価格】

CarriRo® FD(追従モデル):5年リース 月額34,000円(税別)/1台

CarriRo® AD(自律モデル):5年リース 月額52,000円(税別)/ 1台

CarriRo® AD(外部入出力機能搭載モデル):5年リース 月額58,000円(税別) / 1台

CarriRo® AD+ (台車タイプ):5年リース 月額73,000円(税別) / 1台

(パレット積載タイプ):5年リース 月額82,000円(税別) / 1台

【主な製品仕様】

本体重量 |

55kg |

大きさ |

幅61cm×奥行91cm×高さ24cm |

最大積載荷重 |

FD・AD:150kg AD+:200kg |

最大速度 |

時速6km(ドライブ、追従モード) 時速3km(自律移動モード) |

牽引力 |

FD・AD:250N (300kg相当) |

充電時間 |

2時間半 |

稼働時間 |

8時間 ※稼働状況によって異なる可能性があります |

※上記CarriRo® AD+の仕様は変更される可能性がございます。

【CarriRoイノベーションセンターについて】

同センターは、2020年6月より物流無人化ソリューションを一同に集めたショールームとして、東京都枝川に開設されました。台車型物流支援ロボット「CarriRo」シリーズ、無人フォークリフト「CarriRo Fork」をはじめ全機種の実機デモを常時実施しています。

アクセス:

東京都江東区枝川3丁目11-10 月島倉庫 (4F)

JR京葉線・武蔵野線「潮見駅」より徒歩約6分

紹介Web URL: https://www.zmp.co.jp/carriro/innovation-center

【プレスリリース記事】

プレスリリースPDFはこちらからご確認いただけます